China's Best Cable Pulley 3" Wheel for Extension Springs Garage Doors

Product Description

Introducing the Cable Pulley 3" Wheel for Extension Springs Garage Doors - a high-quality accessory designed to enhance the performance of your garage door. This product is made in ZheJiang, China, and is known for its durability and reliability.

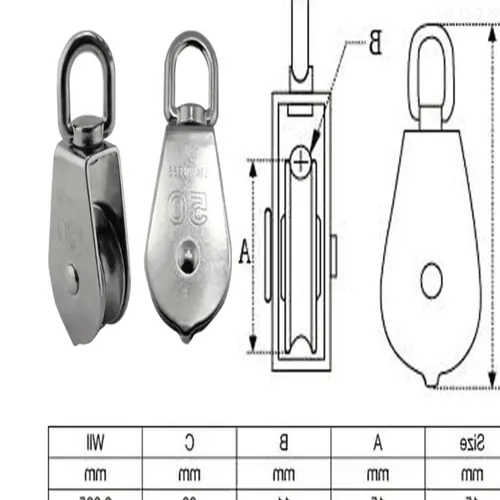

Features and Specifications

- Type: Other Door & Window Accessories

- Place of Origin: ZheJiang, China (Mainland)

- Material: Nylon, Carbon Steel

- Finish: Zinc Plated

- Usage: Orbit

- Name: 2 Inch Galvanized Nylon Roller

- Size: 2''Thickness: 1.2mm Clamp: 2.0mm

- 2 Pcs Cold Rolled Iron With The Thickness Of 1.2mm, 6 Rivets

Frequently Asked Questions

Q: Are you a manufacturer? Do you accept OEM?

A: Yes, we are a professional manufacturer with over 11 years of experience in the spring field. We gladly accept OEM orders. Provide us with your design, and we will quickly create samples for you.

Q: Can you assist with design?

A: Absolutely. Our experienced team specializes in spring design and manufacturing. Simply provide us with your door dimensions, weight, and lifting system, and we will custom design the perfect spring size and weight for your needs.

Q: What are your strengths?

A: Our strengths lie in our competitive pricing, high-quality products, excellent communication with customers, and top-notch after-sales service.

Q: How do you pack your products?

A: We offer standard packing options such as PE bags, plywood cases, wooden cartons, and pallets. Alternatively, we can accommodate any specific packaging requirements you may have.

Q: What is your delivery time?

A: We strive to deliver orders within 3-5 days after confirmation. However, the actual delivery time may vary depending on the quantity of your order.

Our company specializes in supplying various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products, competitive prices, and exceptional customer service. Customization of drawings and samples is welcome.

The content of this page is sourced from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Cable Pulley

Cable pulleys have several performance characteristics that make them highly beneficial in various applications. Firstly, their smooth operation ensures efficient movement of cables, reducing friction and preventing damage. Secondly, their sturdy construction and load-bearing capacity allow them to withstand heavy loads without deformation or breakage. Additionally, cable pulleys are designed to provide precise positioning and control, ensuring accurate movement and alignment. Furthermore, their compact size and versatility make them suitable for use in tight spaces and various environments. Overall, cable pulleys enhance the performance and efficiency of systems where cables are involved.

Types and Characteristics of Cable Pulley

There are different types of cable pulleys available, each with its unique characteristics. One common type is the fixed cable pulley, which is designed to provide stable support and direction to the cable. Another type is the swivel cable pulley, which allows for smoother rotation and movement of the cable in different directions. Additionally, there are cable pulleys with built-in bearings, which further reduce friction and ensure smooth operation. The choice of cable pulley type depends on the specific application and requirements.

Advantages of Cable Pulley Materials

Cable pulleys can be made from various materials, each offering specific advantages. Steel cable pulleys are known for their strength and durability, making them suitable for handling heavy loads. Aluminum cable pulleys, on the other hand, are lightweight and corrosion-resistant, making them ideal for applications where weight and environmental factors are considerations. Nylon cable pulleys offer low friction and quiet operation, making them suitable for applications that require smooth and noise-free movement. The choice of material depends on the desired characteristics and conditions of the application.

Application of Cable Pulley

Cable pulleys find extensive use in various fields, highlighting their value and importance. In the heavy lifting industry, cable pulleys are essential components in cranes and hoists, enabling the safe and efficient movement of heavy loads. In stage equipment, cable pulleys are used for rigging and set changes, ensuring smooth transitions and precise positioning of props. Agricultural machinery utilizes cable pulleys in systems such as hay balers and harvesters to facilitate the movement of agricultural products. Fitness equipment, such as weight machines and cable systems, rely on cable pulleys for smooth and controlled exercise movements. Cable pulleys are also utilized in emergency services equipment, such as rescue systems and evacuation devices, ensuring safe and effective operations in critical situations. The widespread application of cable pulleys across these fields demonstrates their versatility and indispensability.

Future Development Trends and Opportunities

The future of cable pulley products holds promising trends and opportunities. As industries continue to evolve and demand more efficient and reliable systems, cable pulleys are expected to play a significant role. Advancements in materials and manufacturing techniques will lead to the development of high-performance cable pulleys with enhanced durability and load-bearing capacities. Moreover, the increasing focus on automation and robotics in various industries will drive the demand for cable pulleys in precision machinery and robotic systems. Additionally, the growing awareness of safety and ergonomics will create opportunities for the development of cable pulleys with improved features such as noise reduction, ergonomic designs, and enhanced safety mechanisms. The future of cable pulley products is bright, with potential for continued innovation and growth.

Choosing a Suitable Cable Pulley

When selecting a cable pulley, it is important to consider several aspects to ensure compatibility and optimal performance. The load capacity of the pulley must be suitable for the intended application to prevent overloading and system failure. The material of the pulley should be chosen based on factors such as desired strength, weight, and resistance to environmental conditions. The diameter and size of the pulley must be compatible with the cable's dimensions to ensure proper fit and smooth operation. Additionally, the type of pulley, whether fixed or swivel, should be selected based on the specific requirements of the application. Finally, the bore size of the pulley should match the shaft or axle diameter for secure installation and efficient power transmission. Careful consideration of these factors will ensure the selection of a suitable cable pulley for the intended application.

In conclusion, cable pulleys are versatile components that provide numerous benefits in various industries. Their performance characteristics, types, materials, and applications all contribute to their value and importance. The future holds exciting opportunities for the development of cable pulley products, driven by advancements in technology and industry demands. When choosing a cable pulley, careful consideration of factors such as load capacity, material, diameter and size, type of pulley, and bore size will ensure optimal performance and compatibility. Embracing the potential of cable pulleys will lead to enhanced efficiency, safety, and reliability in systems where cables are utilized.

Author: Dream