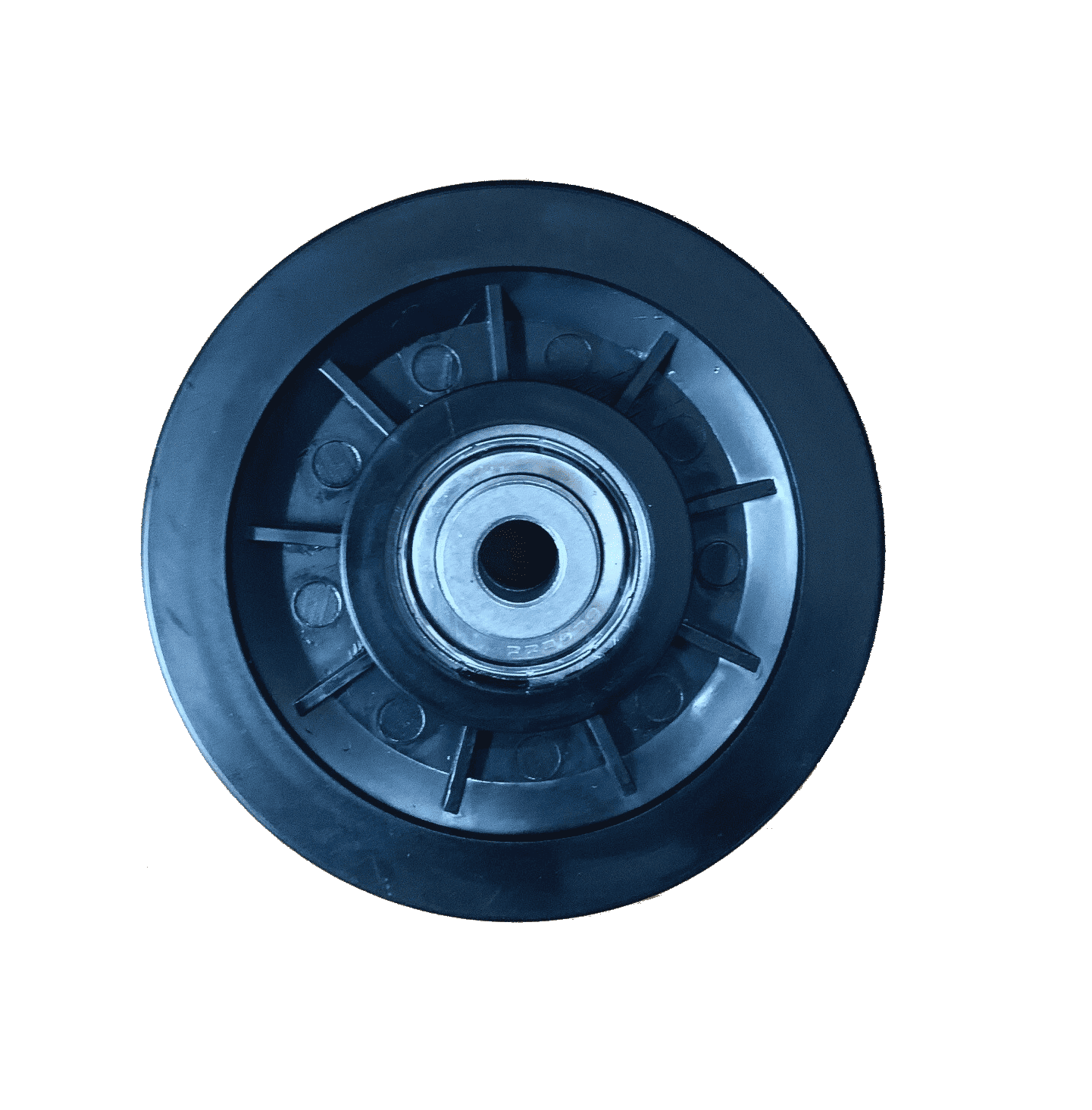

Product Description

Pulley System Gym Timing Belt Alternator Wheels Cable Machine Chain Block Rope Idler Pulleys Motorized Stainless Steel Wire Saw Wall Mount Bearings Manufacturer

Application of Idler Pulleys

Idler pulleys are used in various mechanical systems and applications to redirect or guide belts or chains, change the direction of force transmission, and maintain tension in the system. Here are some typical applications of idler pulleys:

1. Automotive Industry: Idler pulleys are widely used in automotive engines to guide and maintain tension in the timing or serpentine belt systems. They help ensure proper synchronization of engine components, such as the camshaft and crankshaft, and prevent belt slippage.

2. CHINAMFG Systems: Idler pulleys are utilized in heating, ventilation, and air conditioning (HVAC) systems. They help maintain tension in the belts that drive the blower motors, compressors, and other components, ensuring efficient operation and reducing noise and vibration.

3. Industrial Machinery: Idler pulleys find application in various industrial machinery and equipment, including conveyor systems, printing machines, packaging equipment, and textile machinery. They guide and support belts or chains, maintaining proper tension and facilitating smooth and reliable operation.

4. Agricultural Equipment: Idler pulleys are used in agricultural machinery such as combines, tractors, and harvesters. They help guide tension belts that drive components like the grain drill, fan systems, and other moving parts.

5. Fitness Equipment: Idler pulleys are employed in exercise machines, such as treadmills, elliptical trainers, and weightlifting systems. They guide and redirect cables or belts, allowing smooth and controlled movement of exercise components.

6. Material Handling: Idler pulleys are utilized in material handling equipment like forklifts, cranes, and conveyors. They facilitate the movement of goods and materials by guiding and maintaining tension in conveyor belts or chains.

7. Power Tools: Idler pulleys find applications in power tools such as drills, saws, and sanders. They guide and redirect belts or chains, enabling power transfer from the motor to the tool's moving components.

8. Printing and Paper Industry: Idler pulleys are used in printing presses, paper mills, and other paper processing equipment. They help guide and tension belts that drive paper feeders, rollers, and other components, ensuring precise paper movement and consistent printing quality.

9. Robotics and Automation: Idler pulleys are utilized in robotics and automated systems to guide and maintain tension in belts or chains used for linear or rotational motion. They are crucial in ensuring accurate and reliable movement of robotic arms, conveyors, and other automated mechanisms.

These are just a few examples of the applications of idler pulleys. Their versatility and ability to guide, redirect, and maintain tension in belts or chains make them essential components in various industries and mechanical systems.

Related products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How are cable pulleys used in the operation of cranes and hoists?

Cable pulleys play a crucial role in the operation of cranes and hoists. They are an integral part of the lifting mechanism, providing support, guidance, and control for the cables used in these systems. Cable pulleys contribute to the efficient and safe operation of cranes and hoists. Here is a detailed explanation of how cable pulleys are used in the operation of cranes and hoists:

- Lifting Mechanism: Cranes and hoists utilize cable and pulley systems to lift and move heavy loads. The cables are attached to the load and are routed through a series of pulleys. The pulleys are strategically positioned to guide the cables along the desired path. As the cables move, the load is lifted or lowered accordingly. The cable pulleys ensure that the cables are properly aligned and prevent them from tangling or coming off the pulleys. This enables controlled and precise lifting and lowering of loads.

- Load Distribution: Cable pulleys in cranes and hoists help distribute the load weight evenly across the cables. The load is typically attached to multiple cables, and the pulleys ensure that each cable carries its fair share of the weight. This even distribution of load prevents excessive stress on individual cables, reducing the risk of cable failure or system instability. The cable pulleys contribute to the overall balance and stability of the lifting operation.

- Tension Control: Cable pulleys assist in controlling the tension in the lifting cables. Proper tension is crucial for safe and efficient lifting operations. The pulleys are designed to maintain the appropriate tension in the cables during the lifting and lowering processes. They help prevent slack or excessive tension in the cables, ensuring smooth and controlled movement of the load. The tension control provided by the cable pulleys enhances the safety and stability of the crane or hoist operation.

- Directional Control: Cable pulleys enable directional control of the load movement in cranes and hoists. By guiding the cables along specific paths, the pulleys determine the direction of the load. The pulleys can be positioned in various configurations to achieve the desired movement, such as vertical lifting, horizontal shifting, or rotation. This directional control allows for precise positioning and placement of the load, enhancing the versatility and functionality of cranes and hoists.

- Multiple Line Systems: In some cranes and hoists, multiple cables and pulleys are employed to increase lifting capacity or provide additional stability. These systems, known as multiple line systems, consist of several cables connected to the load and routed through corresponding pulleys. The cable pulleys guide and support the multiple lines, ensuring synchronized movement and load distribution. This arrangement enables the lifting of heavier loads while maintaining balance and control.

- Maintenance and Safety: Regular maintenance of cable pulleys is essential for the safe and efficient operation of cranes and hoists. Inspections should be conducted to check for any signs of wear, damage, or misalignment. Lubrication should be applied to the pulleys as recommended by the manufacturer to ensure smooth operation and prevent corrosion. Proper tensioning of the cables should be maintained. Any issues with the cable pulleys or cables should be addressed promptly to avoid potential safety hazards.

In summary, cable pulleys are vital components in the operation of cranes and hoists. They contribute to the lifting mechanism, load distribution, tension control, directional control, and multiple line systems. Proper maintenance of the cable pulleys is essential for ensuring their optimal performance and safety in crane and hoist operations.

What role do cable pulleys play in gym and fitness machines?

Cable pulleys play a significant role in gym and fitness machines, contributing to the functionality, versatility, and effectiveness of various exercise equipment. They are widely incorporated into strength training machines, cable machines, and functional trainers, offering a range of benefits for gym-goers and fitness enthusiasts. Here are some key roles that cable pulleys play in gym and fitness machines:

- Resistance Training: Cable pulleys provide adjustable resistance for resistance training exercises. They allow users to select the desired weight or resistance level by adjusting the weight stack or attaching additional resistance bands. This versatility enables progressive overload and caters to users of different fitness levels, from beginners to advanced athletes.

- Exercise Variation: Cable pulley systems in gym machines offer a wide variety of exercise options. They allow users to perform a range of movements, including pulling, pushing, lifting, and rotational exercises. By adjusting the attachment points and using different handles or attachments, users can target specific muscle groups and engage in a diverse range of exercises, such as lat pulldowns, cable rows, chest presses, bicep curls, tricep pushdowns, and cable flyes.

- Functional Training: Cable pulleys support functional training, which focuses on movements that mimic real-life activities and improve overall strength, stability, and mobility. With cable machines, users can perform exercises that involve multiplanar movements and engage multiple muscle groups simultaneously. This helps enhance coordination, balance, and functional fitness, making cable pulley machines suitable for functional training programs and sports-specific conditioning.

- Core and Stabilization Exercises: Cable pulley machines require users to engage their core muscles and stabilize their bodies during exercises. The continuous tension generated by the cables challenges the core muscles and promotes stability, balance, and coordination. Cable pulley exercises can effectively target the abdominal muscles, obliques, and back muscles, contributing to core strength development and improved posture.

- Range of Motion and Muscle Activation: Cable pulley machines allow users to achieve a full range of motion during exercises. The smooth and controlled movement provided by the pulley system ensures optimal muscle activation and engagement throughout the entire exercise. This increased range of motion helps in maximizing muscle fiber recruitment, promoting muscle growth, and improving flexibility.

- Safe and Guided Exercise Execution: Gym machines equipped with cable pulleys provide a safer and more controlled environment for exercise. The guided movement of the cables reduces the risk of injury associated with free weights and improper form. Additionally, many cable pulley machines incorporate safety features, such as adjustable weight stacks, safety stops, and ergonomic handles, to ensure safe and effective exercise execution.

- Efficient Use of Space: Cable pulley machines are designed to optimize space utilization in gyms and fitness facilities. They often feature compact footprints and multiple cable attachment points, allowing multiple users to perform exercises simultaneously or switch between exercises quickly. This efficient use of space makes cable pulley machines suitable for both commercial gyms and home fitness setups with limited space.

Overall, cable pulleys play a vital role in gym and fitness machines by providing adjustable resistance, exercise variation, functional training capabilities, core engagement, and safe exercise execution. They contribute to effective strength training, muscle development, and functional fitness, making cable-based machines popular among fitness enthusiasts and professionals in the gym industry.

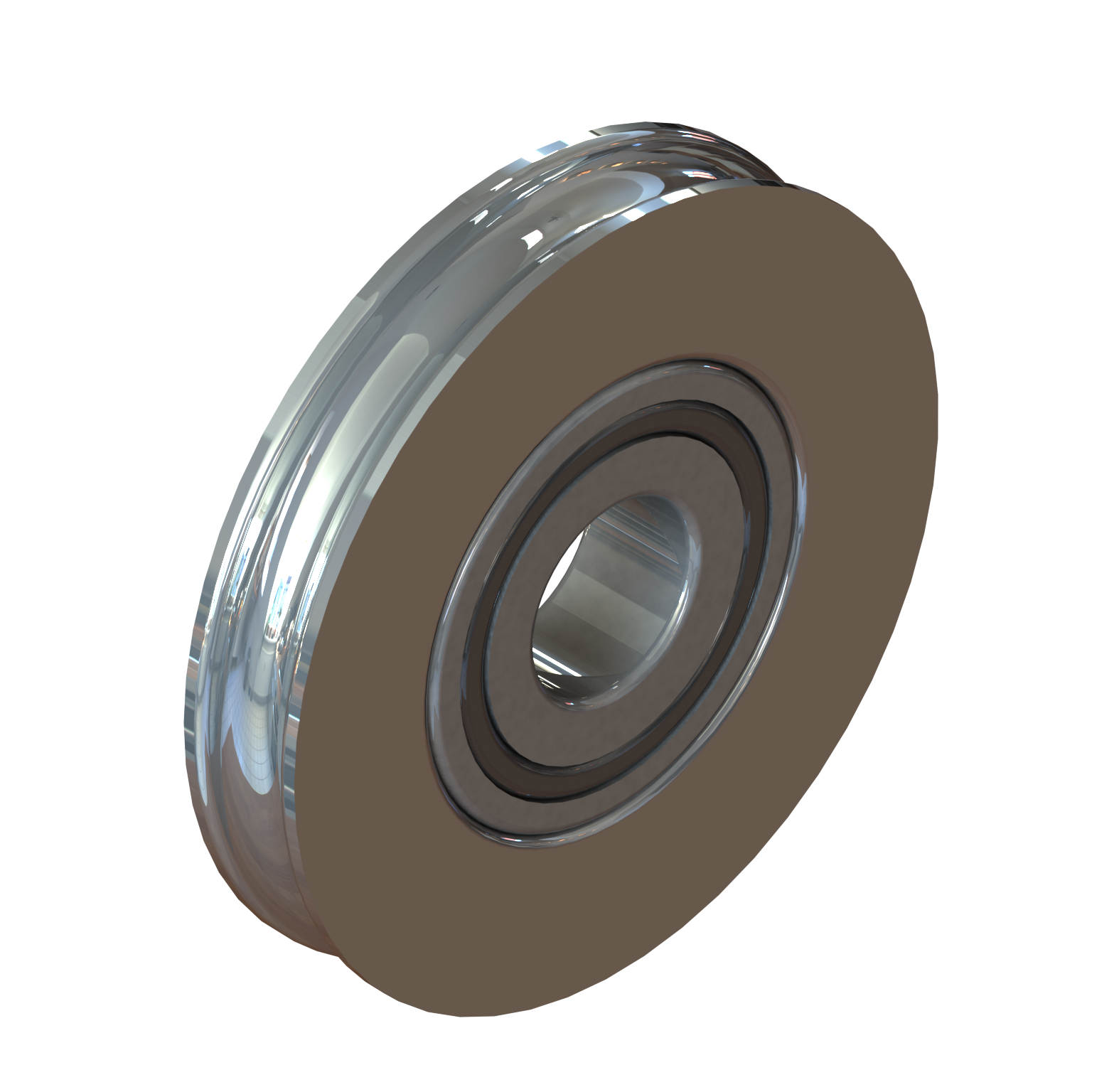

What is a cable pulley, and how is it used in various applications?

A cable pulley, also known as a pulley wheel or sheave, is a grooved wheel that is typically used in conjunction with a cable or rope to change the direction of force and transmit motion. The cable is threaded through the groove of the pulley, allowing it to move along the circumference of the wheel. Cable pulleys are widely used in various applications where force needs to be redirected or mechanical advantage needs to be gained. Let's explore how cable pulleys are used in different industries and applications:

- Fitness and Exercise Equipment: Cable pulleys are commonly found in fitness and exercise equipment, such as weightlifting machines, cable crossover machines, and pulley systems for resistance training. They are used to guide and redirect cables, allowing users to perform exercises that target specific muscle groups. Cable pulleys provide smooth and controlled movement, enabling users to adjust resistance levels and achieve a wide range of exercises for strength training and rehabilitation.

- Mechanical and Industrial Applications: Cable pulleys play a vital role in mechanical and industrial applications where force or motion needs to be transferred, redirected, or lifted. They are used in cranes, hoists, and lifting equipment to change the direction of cables and ropes, allowing for the lifting and movement of heavy loads. Cable pulleys are also employed in conveyor systems to guide and support the movement of materials or products along production lines.

- Material Handling and Rigging: Cable pulleys are extensively used in material handling and rigging applications. They are utilized in construction sites, warehouses, and shipping yards to facilitate the movement of materials, equipment, and cargo. Cable pulleys are often incorporated into rigging systems to create mechanical advantage and enable the lifting or pulling of heavy objects with reduced effort.

- Automotive Industry: Cable pulleys are found in various automotive systems and components. They are utilized in engines for timing belt arrangements, where they help synchronize the rotation of the crankshaft and camshaft. Cable pulleys are also used in vehicle steering systems, enabling the transmission of force from the steering wheel to the steering mechanism, allowing for precise control of the vehicle's direction.

- Window and Door Systems: Cable pulleys are employed in window and door systems to enable smooth and controlled opening and closing. They are used in sliding windows and doors, allowing the cables or ropes to move along the pulley's groove, guiding the movement and ensuring proper operation of the opening mechanisms.

- Entertainment Industry: Cable pulleys are utilized in the entertainment industry for various applications. They are used in stage rigging systems to lift and move scenery, lighting fixtures, and other equipment during performances. Cable pulleys are also employed in aerial acrobatics and flying systems for performers, providing controlled movement and safety during aerial stunts.

Cable pulleys are versatile components that find application in a wide range of industries and scenarios. Whether it's fitness equipment, industrial machinery, material handling, automotive systems, window and door mechanisms, or entertainment rigging, cable pulleys play a crucial role in redirecting force, transmitting motion, and enabling smooth and controlled movement in numerous applications.

editor by CX

2024-05-14