Product Description

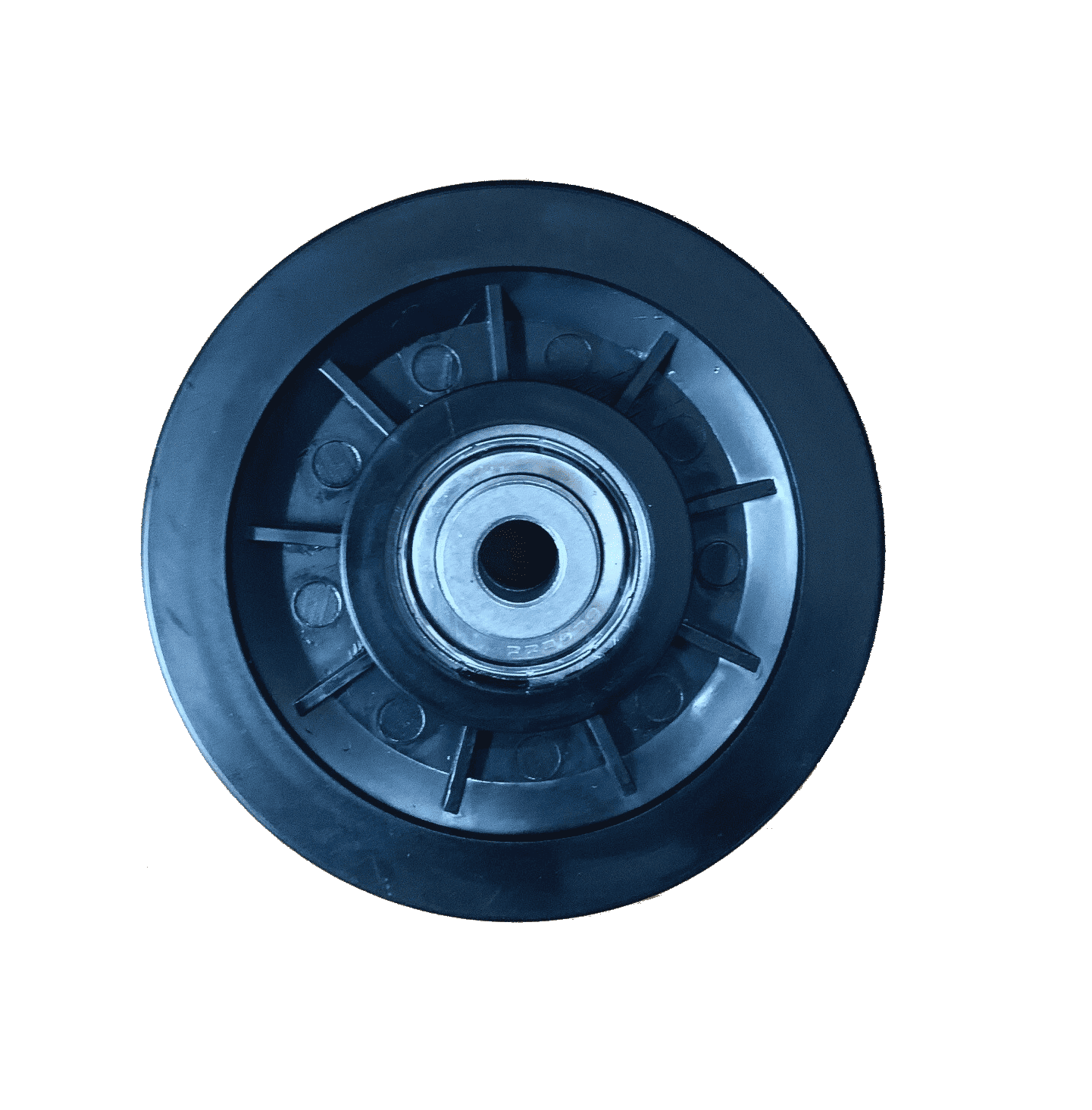

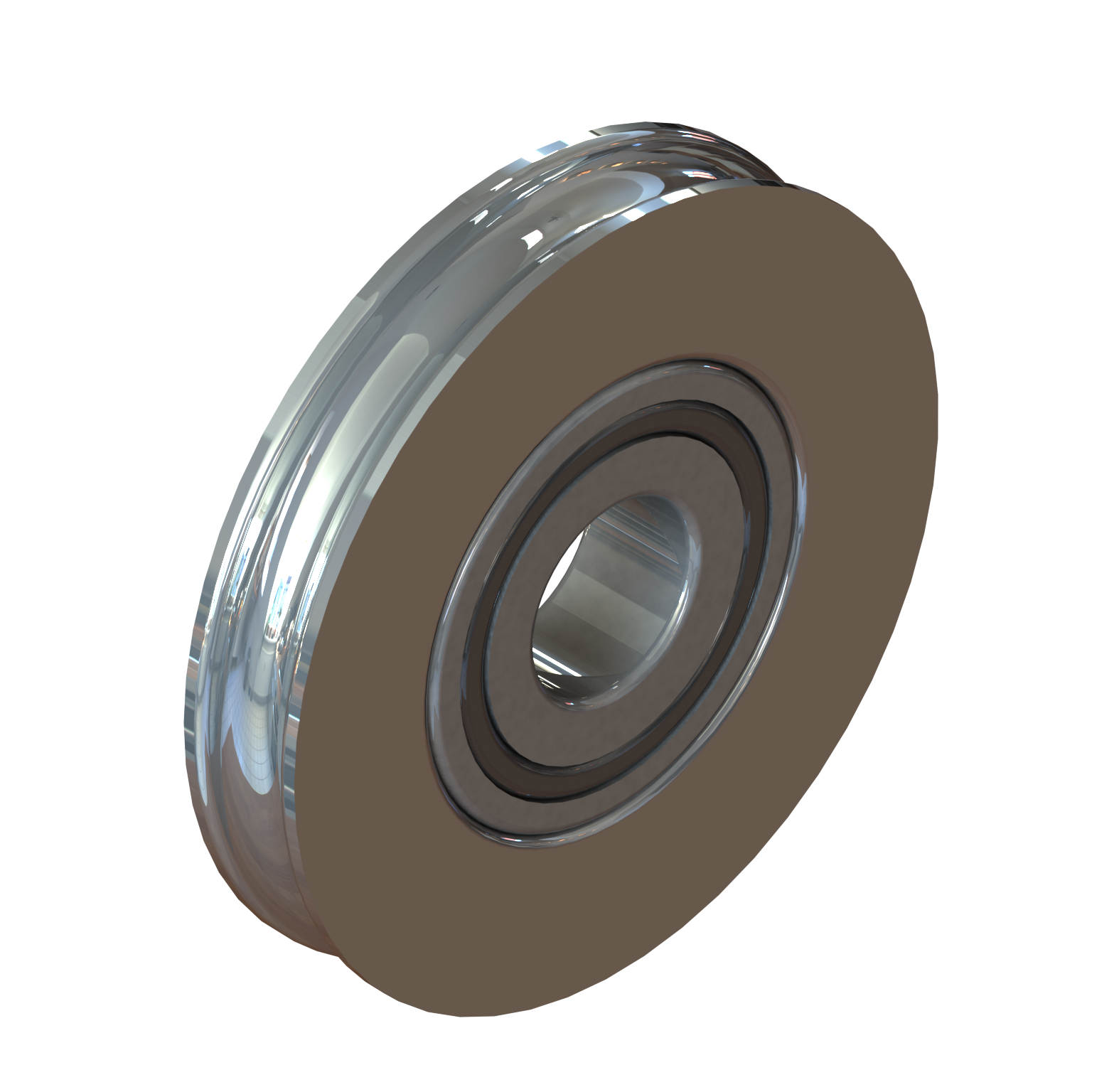

High-Tensile Hard Plastic POM Derlin Movable Rope / Wire / Cable Pulley Rolling

Description

- OEM size suit for customers' requirment

- Multiple color can be choosed

- Engraved or embossed logo accepted

- Large order quantity are able to be fulfilled

- Strict quality control system

- In time delivery and thoughtful custom-service

- Certification: SGS, GB/T 19001-2016, ISO9001:2005

Our Factory

Our Machine

Our Certification

Zhongde is a SGS verified manufacture. We have passed ISO9001:2005 quality control certifacation as well as environment management certification.

For fast quotation, please inform below detials;

1. Product type

2. Size (provide samples or 2d/3d drawings for reference)

3. Material specification (or let us using environment)

4. Quantity request

5. Prefer color

Contact Us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | OEM |

| Manufacturing Process: | Casting |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How are cable pulleys used in the operation of cranes and hoists?

Cable pulleys play a crucial role in the operation of cranes and hoists. They are an integral part of the lifting mechanism, providing support, guidance, and control for the cables used in these systems. Cable pulleys contribute to the efficient and safe operation of cranes and hoists. Here is a detailed explanation of how cable pulleys are used in the operation of cranes and hoists:

- Lifting Mechanism: Cranes and hoists utilize cable and pulley systems to lift and move heavy loads. The cables are attached to the load and are routed through a series of pulleys. The pulleys are strategically positioned to guide the cables along the desired path. As the cables move, the load is lifted or lowered accordingly. The cable pulleys ensure that the cables are properly aligned and prevent them from tangling or coming off the pulleys. This enables controlled and precise lifting and lowering of loads.

- Load Distribution: Cable pulleys in cranes and hoists help distribute the load weight evenly across the cables. The load is typically attached to multiple cables, and the pulleys ensure that each cable carries its fair share of the weight. This even distribution of load prevents excessive stress on individual cables, reducing the risk of cable failure or system instability. The cable pulleys contribute to the overall balance and stability of the lifting operation.

- Tension Control: Cable pulleys assist in controlling the tension in the lifting cables. Proper tension is crucial for safe and efficient lifting operations. The pulleys are designed to maintain the appropriate tension in the cables during the lifting and lowering processes. They help prevent slack or excessive tension in the cables, ensuring smooth and controlled movement of the load. The tension control provided by the cable pulleys enhances the safety and stability of the crane or hoist operation.

- Directional Control: Cable pulleys enable directional control of the load movement in cranes and hoists. By guiding the cables along specific paths, the pulleys determine the direction of the load. The pulleys can be positioned in various configurations to achieve the desired movement, such as vertical lifting, horizontal shifting, or rotation. This directional control allows for precise positioning and placement of the load, enhancing the versatility and functionality of cranes and hoists.

- Multiple Line Systems: In some cranes and hoists, multiple cables and pulleys are employed to increase lifting capacity or provide additional stability. These systems, known as multiple line systems, consist of several cables connected to the load and routed through corresponding pulleys. The cable pulleys guide and support the multiple lines, ensuring synchronized movement and load distribution. This arrangement enables the lifting of heavier loads while maintaining balance and control.

- Maintenance and Safety: Regular maintenance of cable pulleys is essential for the safe and efficient operation of cranes and hoists. Inspections should be conducted to check for any signs of wear, damage, or misalignment. Lubrication should be applied to the pulleys as recommended by the manufacturer to ensure smooth operation and prevent corrosion. Proper tensioning of the cables should be maintained. Any issues with the cable pulleys or cables should be addressed promptly to avoid potential safety hazards.

In summary, cable pulleys are vital components in the operation of cranes and hoists. They contribute to the lifting mechanism, load distribution, tension control, directional control, and multiple line systems. Proper maintenance of the cable pulleys is essential for ensuring their optimal performance and safety in crane and hoist operations.

What advantages do cable pulleys offer for efficient load-bearing and transmission?

Cable pulleys offer several advantages for efficient load-bearing and transmission in various applications. These advantages make them a popular choice in systems where the movement and transmission of heavy loads are required. Here are the key advantages of cable pulleys in load-bearing and transmission:

- Load Distribution: Cable pulleys help distribute the weight of the load over multiple points, reducing the strain on individual components. By spreading the load across multiple pulleys, the stress on each pulley and the supporting structure is minimized. This load distribution improves the overall load-bearing capacity and ensures more efficient and reliable transmission of heavy loads.

- Increased Mechanical Advantage: Cable pulleys provide a mechanical advantage by utilizing the principle of leverage. As the load is transmitted through the cable and around the pulleys, the force applied to move the load is multiplied. This mechanical advantage allows users to move or lift heavier loads with less effort, making load-bearing and transmission more efficient and manageable.

- Directional Control: Cable pulleys offer precise directional control of the load. By changing the arrangement and position of the pulleys, the direction of the cable and the load can be easily altered. This directional control allows for efficient maneuvering of the load, guiding it along the desired path and avoiding obstacles or obstructions. It enables smooth and controlled load-bearing and transmission in various applications.

- Flexibility: Cable pulleys provide flexibility in load-bearing and transmission systems. They can be easily integrated into different configurations and layouts to accommodate specific requirements and spatial constraints. Cable and pulley systems can be designed with various attachment points and angles, allowing for customized load paths and transmission routes. This flexibility makes cable pulleys adaptable to a wide range of applications and load-bearing scenarios.

- Adjustability: Cable pulleys offer adjustability in load-bearing and transmission systems. The tension applied to the cable can be adjusted by changing the position or angle of the pulleys, allowing for precise control of the load. This adjustability is particularly useful when dealing with varying load sizes or when fine-tuning the system to achieve optimal load-bearing and transmission efficiency.

- Smooth and Silent Operation: Cable pulleys are known for their smooth and silent operation. When properly lubricated and maintained, they can provide a quiet and friction-free load-bearing and transmission system. This smooth operation minimizes wear and tear on the components, reduces noise pollution, and ensures efficient and reliable performance in applications where noise reduction is desired.

- Space Efficiency: Cable pulleys offer space-efficient load-bearing and transmission solutions. Compared to other mechanical systems, such as gears or levers, cable and pulley systems require relatively less space. The compact design of cable pulleys allows for efficient utilization of available space, making them suitable for applications where space constraints are a concern.

- Low Maintenance: Cable pulleys require minimal maintenance. With proper installation and periodic inspection, they can operate reliably for extended periods without the need for frequent adjustments or replacements. This low maintenance requirement makes cable pulley systems cost-effective and time-saving in load-bearing and transmission applications.

Overall, cable pulleys offer numerous advantages for efficient load-bearing and transmission. The ability to distribute loads, provide mechanical advantage, offer directional control, flexibility, adjustability, smooth operation, space efficiency, and low maintenance make cable pulley systems highly effective in a wide range of applications, including lifting, material handling, and power transmission.

How do cable pulleys function in lifting and cable-based systems?

Cable pulleys play a fundamental role in lifting and cable-based systems by providing mechanical advantage and facilitating the transmission of force. These systems utilize cable or rope threaded through pulleys to lift or move heavy loads with reduced effort. Let's explore how cable pulleys function in lifting and cable-based systems:

- Mechanical Advantage: One of the key functions of cable pulleys is to create mechanical advantage. By redirecting the path of the cable or rope, pulleys can change the direction of force applied to the load. When multiple pulleys are used in combination, such as in block and tackle systems, they can increase the lifting capacity and reduce the amount of force required to lift a load. This mechanical advantage allows users to overcome the weight or resistance of the load more easily.

- Force Transmission: Cable pulleys serve as a means of transmitting force from one point to another. When force is applied to the free end of the cable or rope, it travels along the groove of the pulley, causing the pulley to rotate. This rotation transfers the force to the load attached to the other end of the cable, resulting in lifting, pulling, or moving the load. The pulley's design and construction are crucial in ensuring efficient force transmission, minimizing friction and energy losses.

- Directional Control: Cable pulleys enable precise directional control in lifting and cable-based systems. By guiding the cable or rope along the circumference of the pulley, they determine the path of movement for the load. This allows users to lift or lower objects vertically, move loads horizontally, or even change the direction of force at various angles. Cable pulleys help to maintain stability and control throughout the lifting or movement process.

- Load Distribution: In lifting systems that use multiple pulleys, such as block and tackle arrangements, cable pulleys help distribute the load weight. As the cable passes through each pulley, the load is divided among the pulleys, reducing the strain on each individual pulley and the cable itself. Load distribution is particularly beneficial in lifting heavy loads, as it minimizes excessive stress on any single component and ensures a more balanced and secure lifting operation.

- Smooth and Controlled Movement: Cable pulleys contribute to smooth and controlled movement in lifting and cable-based systems. They are designed to minimize friction and provide low-resistance guiding surfaces for the cable or rope. This allows for smooth movement of the cable, preventing snags, jerks, or sudden stops that could compromise the safety or stability of the lifting operation. Smooth and controlled movement is essential for precise positioning, accurate load handling, and safe operation of lifting systems.

Overall, cable pulleys function as integral components in lifting and cable-based systems. They create mechanical advantage, transmit force, provide directional control, distribute load weight, and facilitate smooth and controlled movement. By harnessing the mechanical properties of cable pulleys, these systems enable efficient lifting and movement of heavy loads, making them essential in a wide range of industries, including construction, material handling, rigging, and many others.

editor by CX

2024-05-14