Product Description

washing machine pulley mold system gym system gym motorized pulleys crankshaft toothed machine network cable wall mounted stainless steel

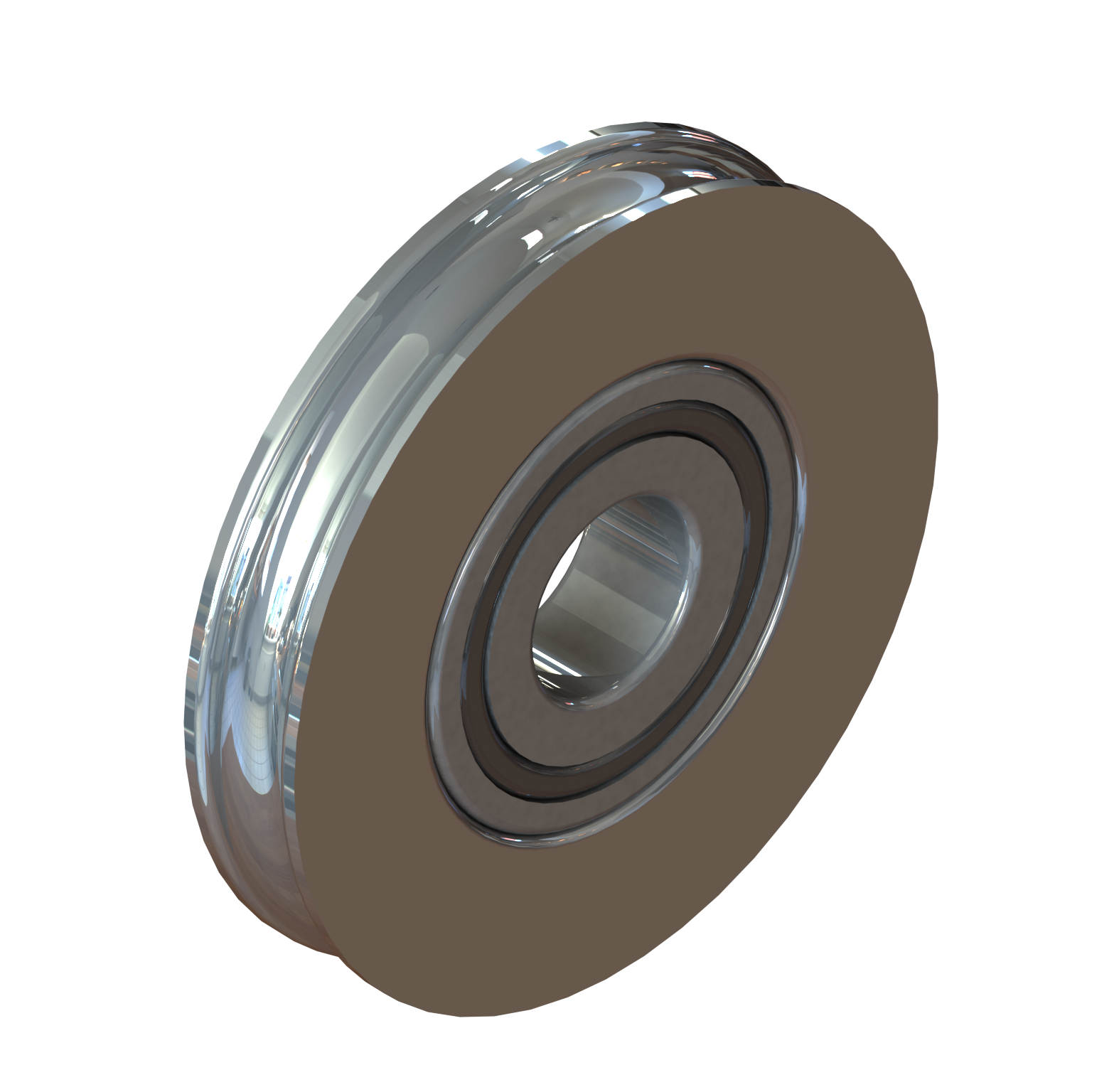

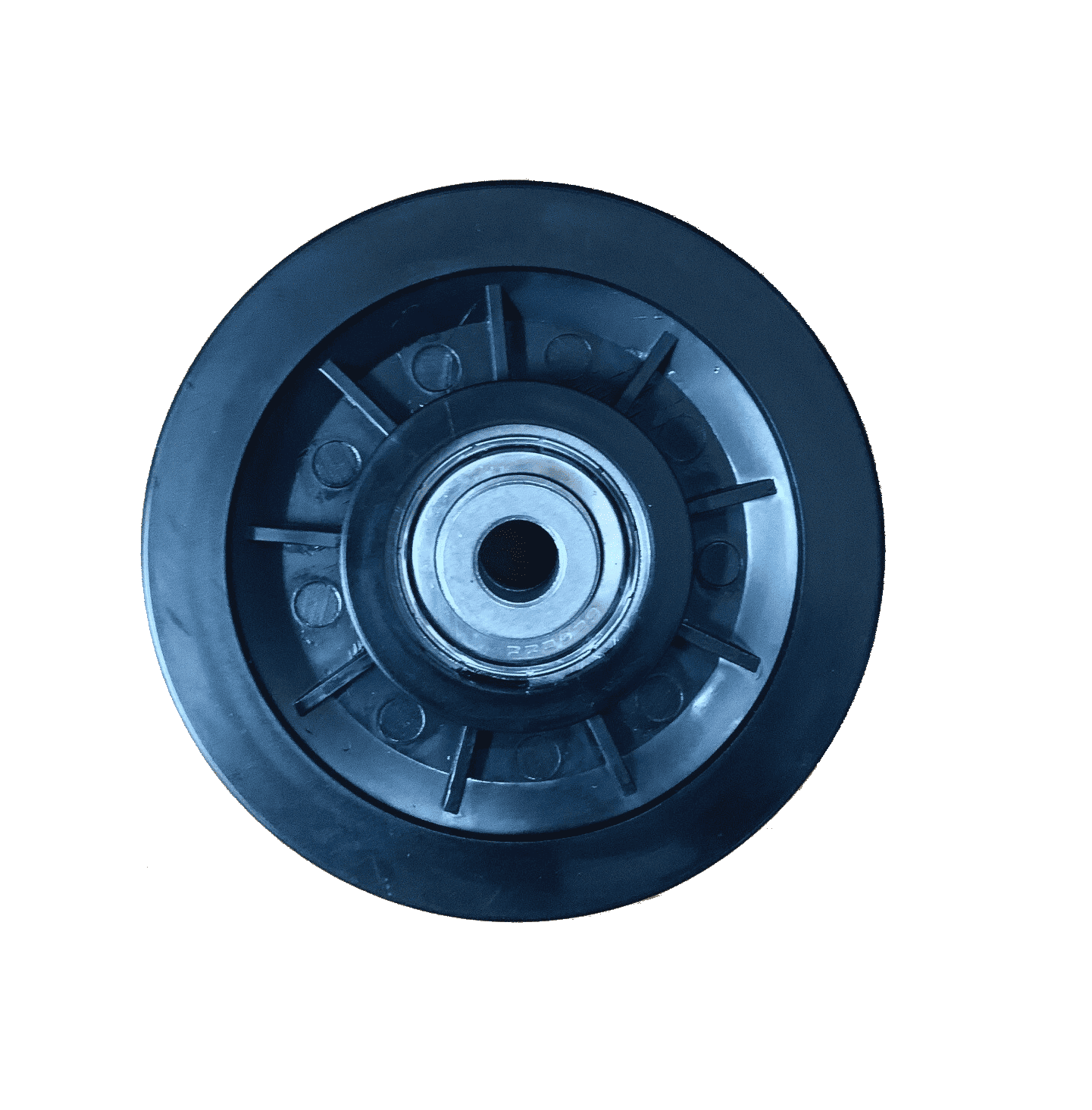

What is washing machine pulley?

A washing machine pulley is a wheel with a grooved rim that is attached to the motor of a washing machine. The belt that drives the drum of the washing machine wraps around the pulley. When the motor turns, the pulley turns, and the belt turns the drum. The pulley is an important part of the washing machine, and it helps to ensure that the drum turns smoothly and efficiently.

Washing machine pulleys can wear out over time, and they may need to be replaced if they become damaged or worn. If you notice that your washing machine is not spinning properly or if the belt is slipping, it is a good idea to check the pulley. If the pulley is damaged, it should be replaced immediately.

Here are some of the symptoms of a damaged washing machine pulley:

- The washing machine drum does not spin smoothly.

- The washing machine belt slips.

- The washing machine makes a loud noise when it is running.

- The washing machine leaks water.

If you notice any of these symptoms, it is important to have your washing machine checked by a qualified technician.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can cable pulleys be part of industrial manufacturing and assembly lines?

Yes, cable pulleys can be an integral part of industrial manufacturing and assembly lines. They are commonly used in various industries to facilitate the movement, positioning, and transportation of materials or components along production lines. Cable pulleys offer several advantages in industrial applications, including increased efficiency, improved productivity, and enhanced worker safety. Here is a detailed explanation of how cable pulleys can be utilized in industrial manufacturing and assembly lines:

Material Handling: Cable pulleys are used to handle and transport materials or products within manufacturing and assembly processes. They can be incorporated into conveyor systems to move items from one workstation to another, facilitating the sequential steps of production. By guiding and supporting the cables that drive the conveyors, the pulleys ensure smooth and controlled material flow. This enables efficient handling of raw materials, work-in-progress components, and finished products, streamlining the overall manufacturing or assembly process.

Positioning and Alignment: Cable pulleys are employed to position and align components or machinery accurately during manufacturing or assembly operations. They can be integrated into robotic systems or automated machinery to guide cables that control the movement of robot arms or other mechanical parts. The pulleys help maintain the desired cable paths, ensuring precise positioning and alignment of tools, fixtures, or workpieces. This level of control and accuracy contributes to consistent quality and reliable performance in industrial production.

Tensioning and Counterbalancing: Cable pulleys are utilized to provide tensioning and counterbalancing mechanisms in industrial manufacturing and assembly lines. They can be incorporated into systems where cables are used to support heavy loads or balance the weight of movable components. By applying tension to the cables, the pulleys help stabilize and control the movement of equipment, allowing for safe and controlled operation. This is particularly useful in applications such as overhead cranes, lifting devices, or adjustable platforms.

Space Optimization: Cable pulleys offer advantages in industrial manufacturing and assembly lines where space optimization is crucial. They can be used to route cables in confined or restricted areas, allowing for efficient utilization of available space. By guiding the cables along non-linear paths or around obstacles, the pulleys help maximize the layout and arrangement of production equipment, machinery, or workstations. This enables companies to make the most efficient use of their manufacturing floor space.

Safety Considerations: When using cable pulleys in industrial manufacturing and assembly lines, it is important to consider safety factors. Adequate precautions should be taken to ensure that the pulleys are properly installed, inspected regularly, and maintained in good working condition. Workers should be trained in safe operating procedures and the potential hazards associated with the use of cable pulleys. Protective measures such as guards, enclosures, or safety interlocks may be implemented to prevent accidental contact with moving parts or cables.

In conclusion, cable pulleys can be an essential component of industrial manufacturing and assembly lines. Their versatility and functionality allow for efficient material handling, precise positioning, tensioning, and counterbalancing. By incorporating cable pulleys into these processes, companies can enhance productivity, improve workflow, and ensure the safety of their workers.

Can cable pulleys be customized for specific machinery and equipment?

Yes, cable pulleys can be customized to suit specific machinery and equipment requirements. Customization allows for the design and production of cable pulleys that are tailored to the unique needs of a particular application. Here is a detailed explanation of how cable pulleys can be customized for specific machinery and equipment:

1. Size and Dimensions: Cable pulleys can be customized in terms of their size and dimensions to ensure compatibility with the machinery and equipment they will be used in. The diameter, width, and overall shape of the pulley can be adjusted to fit the available space and accommodate the specific cable size and type used in the system. Custom sizing ensures proper engagement and optimal performance.

2. Load-Bearing Capacity: Depending on the load requirements of the machinery or equipment, cable pulleys can be customized to handle the desired load-bearing capacity. This involves selecting appropriate materials, reinforcements, and structural design to ensure the pulley can withstand the expected loads without deformation or failure. Custom load-bearing capacity ensures safe and efficient operation.

3. Materials and Coatings: Cable pulleys can be customized by selecting materials and coatings suitable for the specific machinery or equipment environment. For example, in corrosive or abrasive environments, pulleys can be made from stainless steel or coated with protective layers to enhance durability and resistance to wear. Custom materials and coatings enhance the pulley's performance and lifespan.

4. Attachment and Mounting: Cable pulleys can be customized to have specific attachment and mounting options that align with the machinery or equipment requirements. This may involve incorporating flanges, brackets, or other mounting features to facilitate easy installation and secure attachment to the system. Custom attachment options ensure proper integration and stability.

5. Special Features: Depending on the machinery or equipment's unique needs, cable pulleys can be customized with special features or functionalities. This could include the addition of bearings, seals, or specialized grooves to optimize performance, reduce noise, or enhance efficiency. Customized features cater to specific operational requirements.

6. Application-Specific Considerations: Cable pulleys can be customized to meet application-specific considerations. For example, in industries such as mining, aerospace, or manufacturing, where specific regulations or standards apply, pulleys can be customized to comply with those requirements. Customization ensures that the pulleys meet the necessary standards and regulations for the particular application.

7. Quantity and Production: Cable pulleys can be customized in terms of the quantity required for a specific machinery or equipment setup. Manufacturers can produce cable pulleys in the desired quantity, whether it is a small-scale production or a large-scale order. Customization allows for efficient production and supply to meet the specific demand.

In summary, cable pulleys can be customized for specific machinery and equipment by adjusting their size, load-bearing capacity, materials, coatings, attachment options, adding special features, considering application-specific requirements, and producing the desired quantity. Customization ensures that the cable pulleys are precisely tailored to meet the unique needs of the machinery or equipment, resulting in optimal performance, compatibility, and efficiency.

What are the key components and design features of a cable pulley?

A cable pulley consists of several key components and design features that enable its proper functioning and efficient transmission of force. These components and features are carefully engineered to withstand load, reduce friction, and ensure smooth operation. Let's explore the main elements and design characteristics of a cable pulley:

- Wheel or Sheave: The central component of a cable pulley is the wheel or sheave. It is a grooved cylindrical or disk-shaped component that provides a guiding surface for the cable or rope. The groove on the wheel allows the cable to move along its circumference, changing the direction of force. The sheave is typically made of durable materials such as metal or high-strength polymers to withstand the loads and forces applied during operation.

- Bearing: Cable pulleys incorporate bearings to facilitate smooth rotation of the wheel or sheave. Bearings reduce friction between the rotating components, allowing the pulley to rotate freely as the cable moves. Common types of bearings used in cable pulleys include ball bearings or roller bearings, which are selected based on the load capacity, rotational speed, and desired smoothness of operation.

- Axle or Shaft: The wheel or sheave of a cable pulley is mounted on an axle or shaft. The axle provides the central axis of rotation for the pulley and supports the wheel. It is typically made of a sturdy material such as steel or stainless steel to withstand the forces and loads applied during lifting or movement operations. The axle is securely mounted to the framework or structure to ensure stability and proper alignment of the pulley assembly.

- Frame or Housing: Cable pulleys are often housed within a frame or housing that provides support and containment for the pulley components. The frame or housing is designed to maintain the proper alignment of the pulley components, prevent the cable from slipping off the sheave, and protect the internal components from external elements or damage. The frame or housing is typically constructed from materials such as metal or reinforced polymers, ensuring durability and structural integrity.

- Mounting Hardware: Cable pulleys require mounting hardware to securely attach them to the desired location or structure. The mounting hardware may include bolts, screws, brackets, or other fastening mechanisms, depending on the specific application and mounting requirements. The hardware ensures that the pulley assembly remains stable and properly positioned during operation, preventing unnecessary vibrations or movement.

- Surface Finish: The surface finish of a cable pulley is an important design feature that influences its performance. The groove on the wheel or sheave should have a smooth finish to minimize friction and prevent excessive wear on the cable or rope. The surface finish may involve processes such as polishing, coating, or heat treatment to achieve the desired level of smoothness and durability.

- Load Capacity and Safety Factor: The design of a cable pulley takes into account the anticipated load capacity and safety factors. The materials, dimensions, and construction of the pulley components are determined to handle the expected loads without failure or deformation. Safety factors are incorporated to provide an additional margin of strength and reliability, ensuring that the pulley can withstand unexpected peak loads or external forces.

In summary, a cable pulley consists of key components such as the wheel or sheave, bearing, axle or shaft, frame or housing, and mounting hardware. These components, along with design features including surface finish, load capacity, and safety factors, work together to enable smooth operation, efficient force transmission, and reliable performance in lifting and cable-based systems.

editor by CX

2024-05-15