Product Description

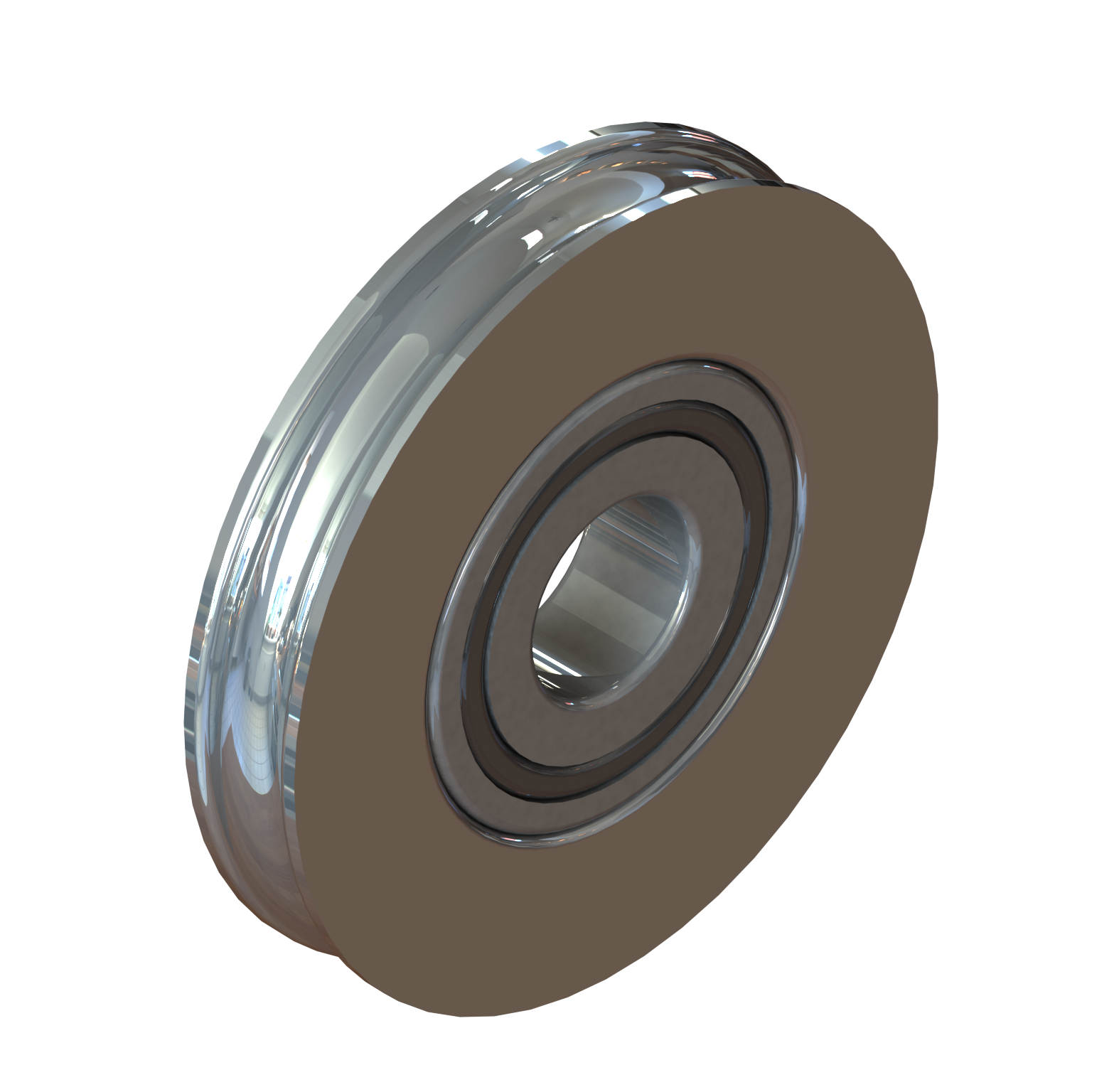

Cable Pulley Ceramic Pulley Wheel Wire Cable Pulley

Cable pulley wheels, wire cable pulley, flanged cable pulley, plastic cable pulley, nylon cable pulley.

Flanged ceramic roller, Wire guide pulleys (ceramic pulleys) is commonly used component when wire passing is required, it can be used in coil winding machine, cable machine and the textile machinery as well. The porcelain ring is mounted on the bearing, Coil winding wire guide pulley(wire roller) will rotate by the thread and wire passing on the surface of the ring. Thus the sliding friction has been converted to the static friction.

But at the start and stop, in order to overcome the inertia, there will be a partial sliding friction. The surface Polish degree of the porcelain ring reaches Ra0.2; The beating during rotation is under 0.15. We select the 99% Al2O3 as the material with the hardness of HRA88 and the density of 3.85...Two nylon side walls have been put to the both side of the ceramic ring and the bearing, coil winding wire guide pulley (wire roller) combines 1 wire roller

Cable pulley wheels, wire cable pulley, flanged cable pulley, plastic cable pulley, nylon cable pulley.

| Specification table of wire roller | |||||

| Modle No | A((mm) | B(mm) | C(mm) | D(mm) | E(mm) |

| HCR001-B03 | 20 | 15 | 3 | 4.8 | 3 |

| HCR002-B04 | 28.7 | 20 | 4 | 6.4 | 4 |

| HCR003-B03 | 30.4 | 15 | 3 | 10 | 3 |

| HCR004-B04 | 40 | 20 | 4 | 15 | 3 |

| HCR045-B04 | 45 | 4 | |||

| HCR045-B05 | 5 | ||||

| HCR045-B06 | 6 | ||||

| HCR005-B05 | 54.5 | 30 | 5 | 10 | 6 |

| HCR005-B06 | 6 | ||||

| HCR005-B07 | 7 | ||||

| HCR005-B08 | 8 | ||||

| HCR006-B07 | 60 | 40 | 7 | 13 | 7 |

| HCR006-B08 | 8 | ||||

| HCR006-B10 | 10 | ||||

| HCR006-B12 | 12 | ||||

| HCR007-B05 | 60 | 30 | 5 | 18 | 6 |

| HCR007-B06 | 6 | ||||

| HCR007-B07 | 7 | ||||

| HCR007-B08 | 8 | ||||

| HCR008-B10 | 79.2 | 50 | 10 | 15 | 9 |

| HCR009-B07 | 80.5 | 40 | 7 | 25 | 7 |

| HCR009-B08 | 8 | ||||

| HCR571-B10 | 99.3 | 50 | 10 | 29.5 | 9 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Logo Printing: | Without Logo Printing |

|---|---|

| Size: | Small |

| Customized: | Non-Customized |

| Type: | Precision translational head |

| Material: | Ceramic |

| Certification: | ISO 9001:2008, ISO 9001:2000 |

| Customization: |

Available

| Customized Request |

|---|

How are cable pulleys used in the operation of cranes and hoists?

Cable pulleys play a crucial role in the operation of cranes and hoists. They are an integral part of the lifting mechanism, providing support, guidance, and control for the cables used in these systems. Cable pulleys contribute to the efficient and safe operation of cranes and hoists. Here is a detailed explanation of how cable pulleys are used in the operation of cranes and hoists:

- Lifting Mechanism: Cranes and hoists utilize cable and pulley systems to lift and move heavy loads. The cables are attached to the load and are routed through a series of pulleys. The pulleys are strategically positioned to guide the cables along the desired path. As the cables move, the load is lifted or lowered accordingly. The cable pulleys ensure that the cables are properly aligned and prevent them from tangling or coming off the pulleys. This enables controlled and precise lifting and lowering of loads.

- Load Distribution: Cable pulleys in cranes and hoists help distribute the load weight evenly across the cables. The load is typically attached to multiple cables, and the pulleys ensure that each cable carries its fair share of the weight. This even distribution of load prevents excessive stress on individual cables, reducing the risk of cable failure or system instability. The cable pulleys contribute to the overall balance and stability of the lifting operation.

- Tension Control: Cable pulleys assist in controlling the tension in the lifting cables. Proper tension is crucial for safe and efficient lifting operations. The pulleys are designed to maintain the appropriate tension in the cables during the lifting and lowering processes. They help prevent slack or excessive tension in the cables, ensuring smooth and controlled movement of the load. The tension control provided by the cable pulleys enhances the safety and stability of the crane or hoist operation.

- Directional Control: Cable pulleys enable directional control of the load movement in cranes and hoists. By guiding the cables along specific paths, the pulleys determine the direction of the load. The pulleys can be positioned in various configurations to achieve the desired movement, such as vertical lifting, horizontal shifting, or rotation. This directional control allows for precise positioning and placement of the load, enhancing the versatility and functionality of cranes and hoists.

- Multiple Line Systems: In some cranes and hoists, multiple cables and pulleys are employed to increase lifting capacity or provide additional stability. These systems, known as multiple line systems, consist of several cables connected to the load and routed through corresponding pulleys. The cable pulleys guide and support the multiple lines, ensuring synchronized movement and load distribution. This arrangement enables the lifting of heavier loads while maintaining balance and control.

- Maintenance and Safety: Regular maintenance of cable pulleys is essential for the safe and efficient operation of cranes and hoists. Inspections should be conducted to check for any signs of wear, damage, or misalignment. Lubrication should be applied to the pulleys as recommended by the manufacturer to ensure smooth operation and prevent corrosion. Proper tensioning of the cables should be maintained. Any issues with the cable pulleys or cables should be addressed promptly to avoid potential safety hazards.

In summary, cable pulleys are vital components in the operation of cranes and hoists. They contribute to the lifting mechanism, load distribution, tension control, directional control, and multiple line systems. Proper maintenance of the cable pulleys is essential for ensuring their optimal performance and safety in crane and hoist operations.

How are cable pulleys utilized in material handling and conveyor systems?

Cable pulleys play a crucial role in material handling and conveyor systems, facilitating the movement, transport, and efficient handling of goods and materials in various industries. They offer several advantages that contribute to the smooth operation and increased productivity of material handling processes. Here is a detailed explanation of how cable pulleys are utilized in material handling and conveyor systems:

- Tensioning and Tracking: Cable pulleys are utilized in material handling and conveyor systems to maintain proper tension and tracking of conveyor belts. They are often positioned at strategic locations along the conveyor line to redirect the belt and ensure it remains aligned and centered. Tensioning pulleys help in maintaining the correct tension in the conveyor belt, preventing slippage, and ensuring smooth and efficient movement of materials.

- Load Support and Weight Distribution: Cable pulleys assist in load support and weight distribution on conveyor systems. They are designed to withstand heavy loads and provide support for the conveyor belt as it carries materials. By distributing the weight evenly, cable pulleys help prevent sagging or excessive strain on the belt, ensuring optimal performance and extending the lifespan of the conveyor system.

- Directional Changes: Cable pulleys are employed in material handling and conveyor systems to facilitate directional changes of the conveyor belt. They are utilized at points where the conveyor line needs to change its path, such as at curves, corners, or diverting stations. By redirecting the belt and guiding it along the desired path, cable pulleys enable the efficient flow of materials and smooth operation of the conveyor system.

- Speed Control: Cable pulleys are used for speed control in conveyor systems. By adjusting the size of the pulleys or changing the pulley arrangement, the rotational speed of the pulley and the conveyor belt can be modified. This allows operators to control the speed at which materials are transported, ensuring optimal throughput, and accommodating different processing requirements or material handling conditions.

- Power Transmission: Cable pulleys play a role in power transmission within conveyor systems. They can be connected to drive motors or other power sources to transmit rotational force to the conveyor belt. This power transmission mechanism enables the movement of the belt and the materials being conveyed, ensuring a continuous flow of goods without manual intervention.

- Conveyor Belt Tension Adjustment: Cable pulleys are utilized for adjusting the tension of the conveyor belt. By incorporating tensioning pulleys in the system, operators can apply the necessary tension to ensure the conveyor belt remains properly tensioned throughout its operation. Proper tensioning is essential for optimal performance, preventing belt slippage, and maintaining consistent material flow.

- Material Sorting and Diverting: Cable pulleys are employed in conveyor systems for material sorting and diverting purposes. They can be integrated into diverters, sorters, or conveyor junctions to redirect materials to different conveyor lines or processing stations based on their specific destination or sorting criteria. Cable pulleys enable efficient material sorting, distribution, and routing within the material handling system.

- Overhead Conveyor Systems: Cable pulleys are commonly used in overhead conveyor systems, where the conveyor belt is suspended from overhead tracks or cables. The pulleys in these systems help support the weight of the belt and the materials being conveyed while allowing smooth movement along the designated path. Overhead conveyor systems are often utilized in industries such as automotive manufacturing, warehousing, and distribution centers.

Overall, cable pulleys are essential components in material handling and conveyor systems. Their utilization in tensioning, tracking, load support, directional changes, speed control, power transmission, tension adjustment, and material sorting contributes to the efficient and seamless movement of goods and materials, enhancing productivity and streamlining material flow in various industrial applications.

How do cable pulleys contribute to effective weightlifting and exercise equipment?

Cable pulleys play a crucial role in weightlifting and exercise equipment, contributing to effective and versatile workout routines. They offer several advantages that enhance the effectiveness of strength training, resistance exercises, and overall fitness. Here are some ways in which cable pulleys contribute to effective weightlifting and exercise equipment:

- Variable Resistance: Cable pulleys provide variable resistance throughout the range of motion, allowing users to adjust the resistance level based on their fitness goals and capabilities. By changing the position of the pulley attachment points or adjusting the weight stack, users can modify the resistance applied during exercises. This versatility enables progressive overload, which is essential for muscle growth, strength development, and improving overall fitness.

- Multidirectional Movement: Cable pulley systems offer multidirectional movement, enabling exercises that involve pulling, pushing, lifting, and rotational movements. This versatility allows users to target different muscle groups and perform a wide range of exercises, including rows, chest presses, lat pulldowns, bicep curls, tricep pushdowns, and core rotations. The ability to perform exercises in various planes of motion contributes to overall muscle balance, functional strength, and improved athletic performance.

- Stabilization and Core Engagement: Cable pulley exercises require users to engage their core muscles and stabilize their bodies throughout the movements. The pulley's continuous tension and resistance challenge the core muscles, promoting stability, balance, and coordination. This engagement of the core muscles is beneficial for developing a strong and stable core, which is essential for overall strength, posture, and injury prevention.

- Isolation and Functional Training: Cable pulleys allow for both isolation exercises, targeting specific muscle groups, and functional training exercises, mimicking real-life movements and activities. Users can perform exercises that isolate individual muscles or perform compound movements that engage multiple muscle groups simultaneously. This versatility makes cable pulleys suitable for a wide range of fitness goals, whether it's muscle building, strength training, rehabilitation, or sports-specific conditioning.

- Range of Motion and Muscle Activation: Cable pulleys enable a full range of motion during exercises, ensuring optimal muscle activation and engagement. Users can achieve a greater stretch and contraction of the muscles due to the unrestricted movement provided by the pulley system. This increased range of motion helps in maximizing muscle fiber recruitment, promoting muscle growth, and improving flexibility.

- Safety and Controlled Movement: Cable pulley systems often incorporate adjustable weight stacks, safety features, and smooth pulley mechanisms that allow for controlled and safe movement. The use of cables reduces the risk of injury associated with free weights, as users can perform exercises with guided and predictable movements. The ability to adjust the resistance and customize the exercise intensity also enables users of different fitness levels to safely and effectively perform exercises.

The versatility, adjustability, and smooth operation of cable pulleys make them valuable components in weightlifting and exercise equipment. They provide users with a wide range of exercise options, promote muscle growth, strength development, and functional fitness. Cable pulleys contribute to effective workouts by offering variable resistance, multidirectional movement, core engagement, and controlled exercise execution, making them popular in both commercial gyms and home fitness setups.

editor by CX

2024-03-14